At about 14:38 on March 21, a China Eastern Airlines Boeing 737-800 passenger plane crashed in the mountains of Teng County, Wuzhou City, Guangxi. The plane dived vertically to the ground, descended 8,000 kilometers in two minutes, exploded and disintegrated, and with a roar, the whole people mourned.

In order to understand the cause of the plane crash, rescuers also began to search for the "black box" while doing their best to search and rescue.

The mysterious "black box" is the hot topic of every crash, why can it tell us the cause of the crash?

In 1992, the China Southern Airlines flight crash also occurred in Guangxi. One day after the incident, rescuers found the "black box" in the forest near the crash site. Afterwards, he was rushed to Shanghai for identification and deciphering. After searching the flight log book and 9 data tapes, he was able to understand the final cause of the plane crash.

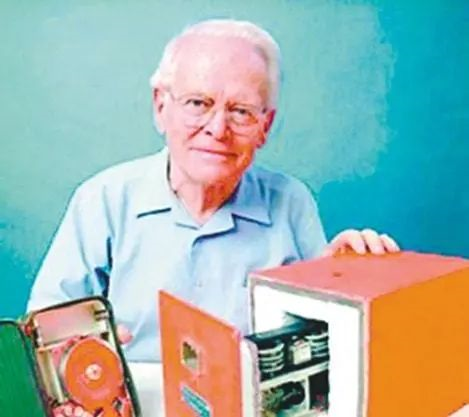

In 1953, Dr. David Warren of Australia invented the world's first black box, which can retain 4 hours of voice and flight data. In 1958, Dr. Warren received funding to start mass production of black boxes in the UK, and governments around the world have ordered that civil and military aircraft must be equipped with black boxes. The black box became a hot research topic in the scientific community at that time. After more than 60 years of development, the data retention time of the black box has now been extended from 4 hours to at least 30 days.

The black box is the largest container for aircraft data storage. It can also be simply understood as a large-capacity mobile phone memory card. All output data and input data on the aircraft are all collected in the black box. No matter what happens to the aircraft system, it will not stop. The action of storing data, and all data is preserved intact.

By deciphering the data of the black box, we can know the conversations, transmissions and other sounds in the cockpit and cabin before the plane crashed. Another part of very important data is the various parameters of the aircraft before the crash, such as acceleration, attitude, altitude, thrust, fuel volume, position of the control surface and a series of parameters. Using these retained data, the cause of the crash can be comprehensively analyzed.

In order to prevent the black box from being damaged when the aircraft explodes, its shell is made of very thick steel plates and many layers of heat-insulating, impact-resistant and pressure-resistant protective materials. In addition, the core that supports the black box to retain all input data and output data is the circuit board and components on the circuit board.

The following is a photo of the black box disassembled by others. After dismantling the outer steel plate, you can see the green circuit board at a glance.

The green circuit board inside the black box is covered with multiple black main control chips of different sizes, as well as capacitors, resistors, sensors, transformers, inductors, potentiometers, diodes, triodes, transistors, etc. Arranged spectacularly and orderly on this brick-sized green circuit board.

To make the black box work normally, one depends on the above electronic components, and the other is the green printed circuit board. However, if the electronic components are separated from the circuit board, they cannot perform their functions, and they are just useless hardware. Therefore, the normal operation of the black box is actually the most important thing is the printed circuit board.

Before producing the black box, the engineer will first carry out the schematic design and PCB design. The electronic components we see above will be replaced by virtual devices in the PCB design and completed on the PCB software. In the past, Protel software was traditionally used, and now there are some new PCB drawing software.

After the PCB is drawn, it is sent to the manufacturer for mass production. The positions of the virtual electronic components will be welded with real devices one after another, so that the circuit board electrically connects the components, and the function of the circuit board set in the schematic diagram is thus realized.

In order to ensure that the circuit boards in the black box will not be stopped due to the interference of the bad external environment when the plane explodes and crashes, it is accompanied by strict requirements on the performance of the circuit boards. The circuit boards used in the black box must have high stability, high Reliability, pressure resistance, high temperature resistance, low power consumption and other high requirements can support the black box to operate at high frequency and high speed in harsh environments.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd