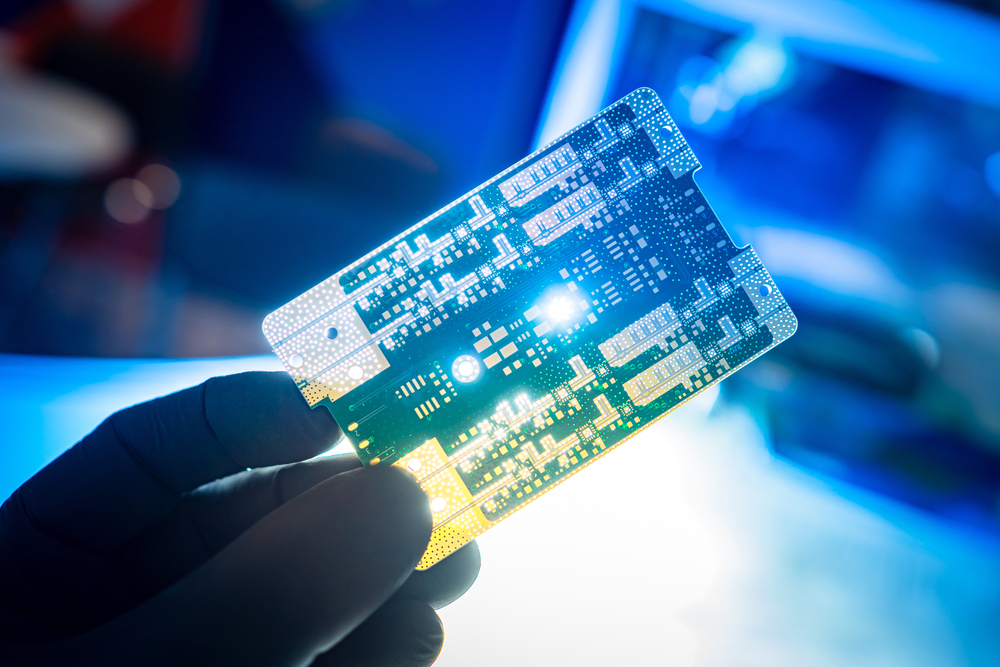

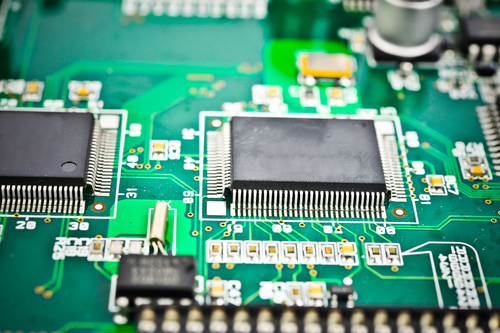

The use of conformal coating is an essential part of all high-quality PCB production processes. Assuming the form of a thin polymeric film, this toughened barrier provides printed circuit boards with an appropriate level of protection from the many external and environmental influences that may impact their performance and durability.

At Ruiputuo , conformal coating is offered to all of our clients as part of our extensive range of PCB manufacturing services. We use market-leading techniques and technology to ensure that conformal coating is applied to a circuit board in accordance with your requirements, without ever compromising on quality.

Read on to learn more about this vital process.

Do I Need Conformal Coating?

Although all PCB designs are different, the simple answer to this question is “yes”. Opting for this feature can ensure that the solder joints, exposed traces and electronic components that make up your PCB remain protected from damage and corrosion when put to use in any environment. The addition of a protective coating can also increase the lifespan of your PCB, guaranteeing reliability and high performance at every turn.

Suitable for use in a wide range of environments, such as those encountered by military and automotive applications, conformal coating has been proven to eliminate problems caused by factors such as electrical failures and exposure to heat. Its use supports closer track spacing and higher voltages, opening clients and specialists up to an extensive realm of PCB design possibilities.

Different Types Of Conformal Coating

Just as every electronic assembly is unique, so too are the many different types of conformal coating on offer. Acrylic, polyurethane and silicone resins are perhaps the most common of these, and each have their own advantages.

Acrylic conformal coating, which is what our experts use here at Ruiputuo , is notable for its high dielectric strength. It offers excellent protection against humidity and salt mist, whilst possessing superior adhesive capabilities. A further advantage is that it can be easily removed, which makes rework and repair very simple.

Polyurethane coating is chosen for PCBs that require protection from chemicals and moisture. It is resistant to abrasion and can often be found in aerospace environments. This material remains flexible even at low temperatures.

Silicone-based conformal coating thrives in several different environments and works within a very wide temperature range. Its flexibility also makes it a good choice for PCBs that need to be protected from moisture, chemicals and sea salt.

Conformal Coating Application Methods

The different forms of conformal coating can be applied in several ways. This method of application is usually dependent on the requirements of the board and the client, as well as the equipment a PCB manufacturer has at their disposal.

For low-volume applications, many choose to brush the coating onto the PCB manually. Such a technique requires a practised hand, and may be the way to go for rework or repair. Elsewhere, it’s not uncommon for PCB manufacturers to use handheld aerosol cans or spray guns to apply the conformal coating. Again, as this is a delicate process, it should only be attempted by someone with sufficient knowledge and experience of spraying techniques.

Larger companies, such as Meizhou Ruiputuo Technology Co.,Ltd, rely on specialist machinery to automate the conformal coating process. This can include programming a system to complete a set of application tasks or overseeing a dipping process in which the circuit board is immersed in the coating solution. The latter requires the PCB to undergo masking beforehand. Both of these methods of application should be carried out under the watchful eye of industry experts, who will be required to follow strict quality control processes.

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd