Flex and Rigid-Flex PCB Design

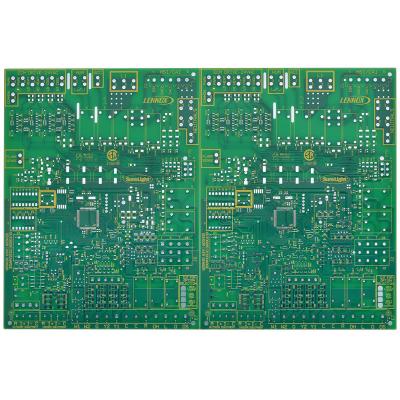

For many circuits, particularly those used in high-speed digital communication systems, it is crucial that the printed circuit board (PCB) accurately follows the circuit’s design. Flexible and rigid flex boards are two popular PCB technologies whose differences lie in how they implement the interconnects and trace layout onto a PCB.

Flex and rigid flex circuit boards serve many diverse applications ranging from medical devices, cell phones, and military electronics, to name a few. They are a great product to use within the fast-paced and ever-changing technology environment. Their flexible nature allows for more design freedom and systems integration, and their ability to bend to any desired shape allows for easy integration into embedded systems.

Flex and rigid flex PCB design technology are changing drastically, although many designers and engineers may not be thoroughly familiar with how flexible circuits differ from rigid flex PCBs. This guide will explain the two types of designs and help you understand both the technologies and their significance.

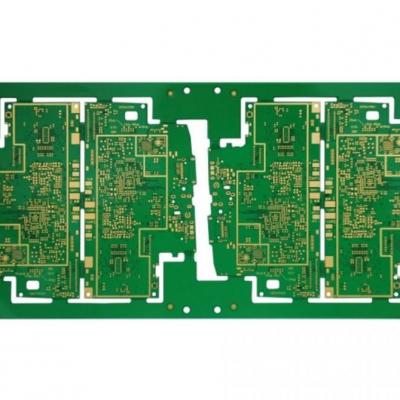

Flex PCB Design Technology

Designing a flex circuit requires special care and attention to detail. The design must account for the fact that the circuit will be subjected to stress during its lifetime. Designing a flex circuit starts with determining what the product needs to do. Engineers create schematics for all components on the board using computer-aided design software (CAD). This process involves selecting appropriate materials for each component, including copper traces for electrical connections between components. Once everything is designed, engineers create Gerber files that manufacturers can use to make prototypes or production runs of boards.

The flex PCB manufacturing process is similar to standard PCB manufacturing but with some key differences. Flex boards are made using copper-clad FR-4 fiberglass laminate as the base material, which is then etched and plated with copper. After this process, an adhesive layer is applied to one side of the flex circuit board to allow it to be bonded to other components or assemblies.

Flex PCB Design Key Benefit

The key benefit of using flex circuit technology is that it allows for creating smaller, lighter, and more flexible electronic devices than traditional PCB manufacturing techniques. Flexible circuits can also be used in products such as smart cards and RFID tags, which can be placed onto clothing or integrated into other objects. A typical application for flex circuits is the design of wearable electronics such as fitness trackers or smart watches, which require flexible components that can bend around the wrist or other body parts without breaking.

Crucial Factors for Flex PCB Design

There are several factors that must be taken into consideration when designing flex circuits:

Material for the substrate

The material used for the substrate has an enormous impact on the performance of the circuit board. Flex circuits can be made from various materials like polyester film, polyimide, polyester, or epoxy.

Size and shape

You need to consider what size and shape you want your flex circuit board to be and how many layers it should have. For example, if you want to make a single-sided flex PCB, you need to consider this before designing it.

Thickness

Depending on what material you choose for your flex circuit board, different thicknesses will be available for use with them. You also need to consider how thick each layer should be so they do not overlap when they come together during assembly or installation in an end product.

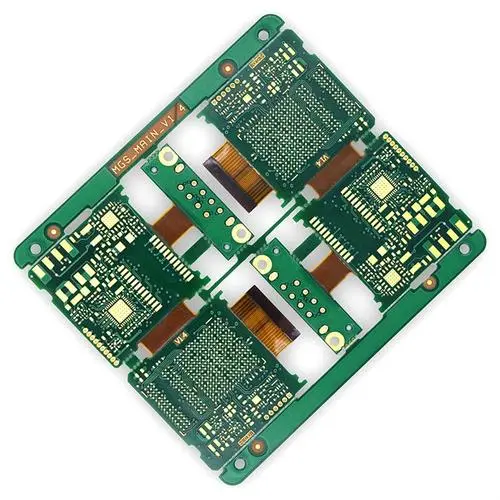

Rigid Flex PCB Design Technology

Rigid flex PCB design technology, one of the most advanced manufacturing processes for flexible circuit boards, is used to manufacture a board with both rigid and flexible properties. The development of rigid flex PCB design technology has made it possible to create flexible PCBs with high-performance components embedded in them. Rigid flex PCBs are a cost-effective solution for high-volume applications that require flexibility. They can bend and flex in any direction while maintaining the same electrical performance as traditional rigid PCBs.

The Rigid Flex PCB design process combines two standard PCB processes: rigid PCBs and flex circuits. However, the rigid flex PCB design process consists of two main steps: the first step involves printing the substrate material onto a flexible substrate using a silk screen or pad printing method; the second step involves laminating the printed material with a thin layer of copper which forms an electrical circuit pattern on both sides of the board. The final product is then cut into individual pieces using a laser cutter or other cutting tool. These flexible printed circuit boards are made of polyimide substrate that can be flexed or bent without damage or warping.

Rigid Flex PCB Design Key Benefit

The most significant advantage of using rigid flex circuits over other types of PCBs is that they can be made extremely thin while still retaining their electrical conductivity and mechanical strength. They are also much lighter than conventional PCBs, so they do not add any extra weight to the device, making them ideal for applications where weight is an issue, such as mobile phones or tablets, where size and weight matter more than anything else.

Crucial Factors for Rigid Flex PCB Design

There are several factors that must be taken into consideration when designing rigid flex circuits:

Type of Material

This depends on what you are using the PCB for and how it will be used. Rigid flex boards can be made from various PCB materials, including copper-clad FR4, glass-reinforced epoxy laminate, and ceramic-based materials.

Size and Shape

The size of the rigid flex circuit is determined by the number of layers and the size of each layer. The shape depends on the design, but it can be made in any desired shape by joining several layers together at the required locations.

The rigid flex PCB design uses a conductor layer, insulation layer, and ground layer. It also has a plated through hole that allows the connection of two or more layers by passing a conductor through them. The purpose of this technique is to provide flexibility to the board while it remains rigid. In contrast, the flexible flex PCB design is used for circuit boards with multiple layers of conductors and insulators. The main difference between this type of circuit board and others is that it contains only one layer of metal on its surface, making it flexible enough to be bent without breaking or cracking.

Thickness of Board

The thickness of your rigid flex circuit will depend on what you are trying to achieve with your design. For example, if you want an extremely durable product, you would use a thicker material such as glass-reinforced epoxy laminate.

Conclusion

When it comes to PCB design, you will find a few differences between rigid-flex and flexible PCBs. Which PCB is better for your circuit board needs depends on your preferences and specific project requirements, but both options are generally suitable for most circuits. Rigid-flex and flexible displays are very different; one can change shape, while the other can be bent. You may find the differences subtle, but knowing them could be crucial to the success of your circuit. To learn more about the capabilities of both types of PCB, check out Hemeixin.

rpttechpcb is Professional production low-cost PCB,Cheap PCB, Low price for PCB,94V0

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd