1. Definition of thick copper plate

Thick copper board refers to a printed circuit board with a copper thickness ≥ 3oz on any layer of the inner layer or outer layer.

Second, the characteristics of thick copper plate

Thick copper plate has the characteristics of carrying large current, reducing thermal strain, and good heat dissipation.

1. Thick copper circuit board can carry large current

In the case of a certain line width, increasing the copper thickness is equivalent to increasing the cross-sectional area of the circuit, so that it can carry a larger current, so it has the characteristics of carrying a large current.

2. Thick copper circuit board reduces thermal strain

Copper foil has a small electrical conductivity (also called resistivity, 1.72*10-8ΩΩ m) and the temperature rise is small under the condition of large current, so it can reduce the heat generation, thereby reducing thermal strain.

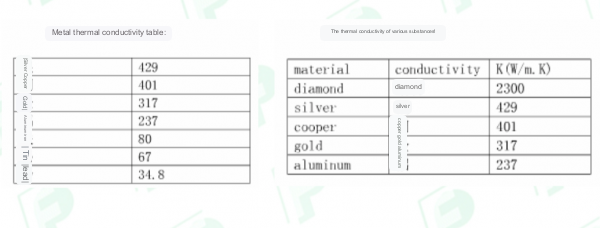

Conductivity is the resistivity. Metal "conductors" are divided into:

Silver→copper→gold→aluminum→tungsten→nickel→iron.

3. Thick copper circuit board has good heat dissipation

Copper foil has high thermal conductivity (thermal conductivity 401W/mK), which can play an important role in improving heat dissipation performance, so it has good heat dissipation;

Thermal conductivity refers to the heat transfer through an area of 1m2 within 1H for a material with a thickness of 1m and a temperature difference of 1°C between the two sides under stable heat transfer conditions. The unit is W/m·K.

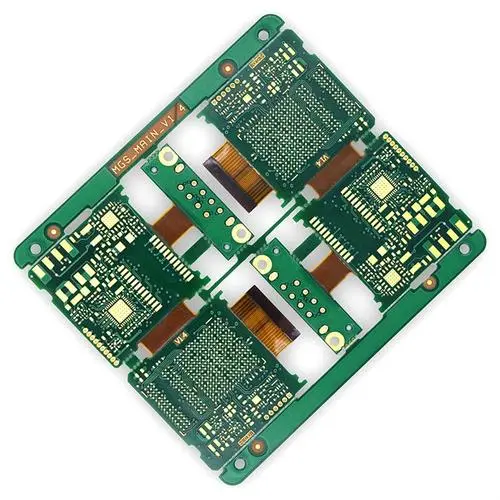

3. Market application of thick copper plate

The application field and demand of thick copper plate have been rapidly expanded in recent years, and it has become a kind of "hot" PCB variety with good market development prospects.

The vast majority of thick copper plates are high-current substrates (current x voltage = power). The main application areas of high-current substrates are two major areas: power modules (power modules) and automotive electronic components. Some of its main terminal electronic products are the same as conventional PCBs (such as portable electronic products, network products, base station equipment, etc.), and some are different from conventional PCB fields, such as automobiles, industrial control, power modules, etc.

High-current substrates are different from conventional PCBs in terms of efficacy. The main function of conventional PCB is to form wires for transmitting information. The high-current substrate has a large current passing through it, and the main function of the substrate carrying power devices is to protect the carrying capacity of the current and stabilize the power supply. The development trend of this kind of high-current substrate is to carry more current, and the heat emitted by larger devices needs to be dissipated. Therefore, the large current passing through is getting larger and larger, and the thickness of all copper foils on the substrate is getting thicker and thicker. The 6oz copper thickness of the high-current substrate manufactured now has become routine;

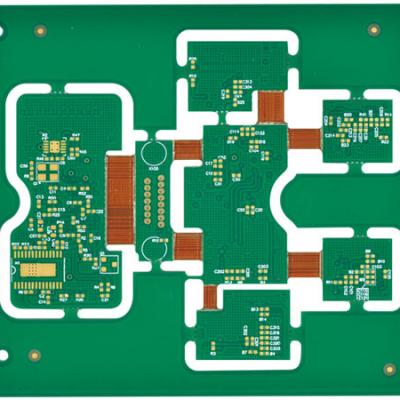

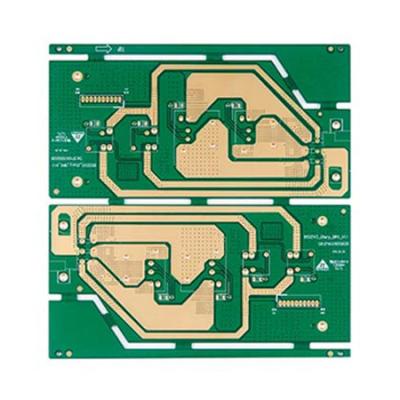

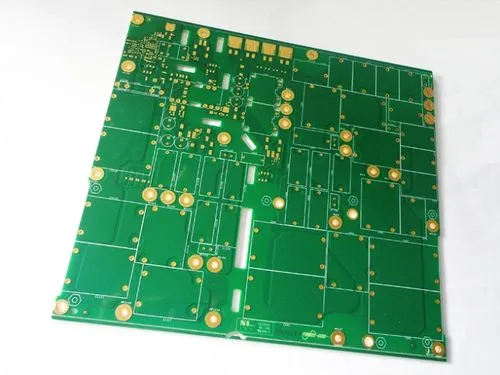

Thick copper circuit board

Meizhou Ruiputuo Technology Co.,Ltd

Meizhou Ruiputuo Technology Co.,Ltd